What We Do

We Recycle the End of Life Plastics

PROBLEM

Waste plastic can lead to serious soil, water and air pollution and can pose a threat to communities, cities and some of Earth’s greatest landscapes and oceans.

SOLUTION

We have developed an innovative pyrolysis technology that can safely and effciently transform waste into clean fuels.

CUSTOMERS

Our technology is provided to waste management organisations and communities that have the infrastructure to continuously transform waste materials into usable clean fuels.

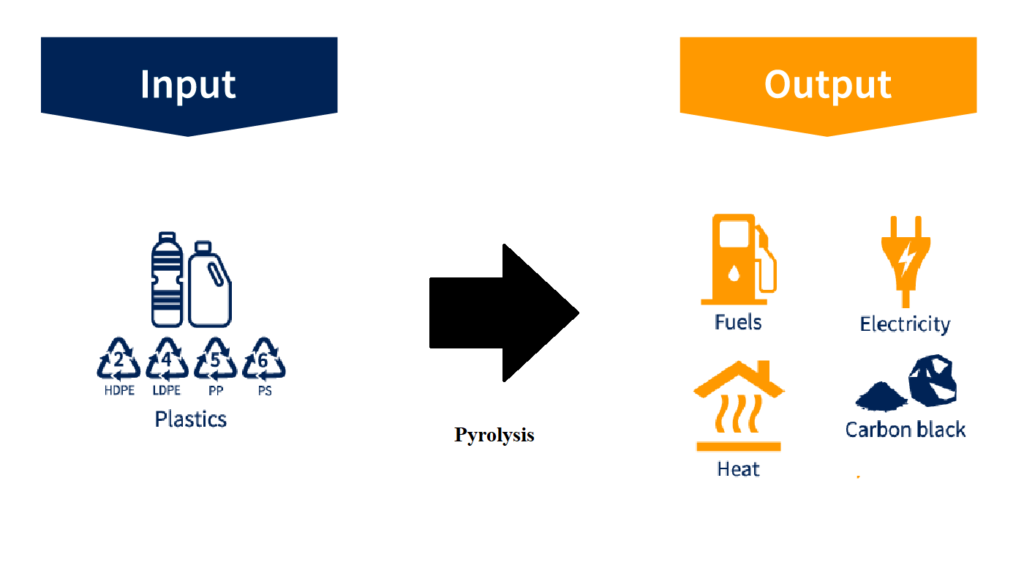

How does Pyrolysis work?

A pyrolysis plant is designed for the thermochemical processing and utilization of biomass and other organic polymeric wastes to produce liquid and organic products as well as fine char.

There are various types of pyrolysis technologies, but the process is always the same:

The heart of each plant is the reactor. Here, heat is used to thermally crack the dry feedstock, excluding oxygen. At the microscopic level, organic compounds are split and large molecules are broken down into smaller ones without combustion due to the exclusion of air. Far less CO₂ and energy is released from the feedstock, which leads to new energy-rich reaction products. A vapor-gas mixture and fine coke is produced.

In the following step, the mixture is separated from the charring dust. During a cooling process, the condensation of the mixture separates the liquid pyrolysis products (bio-oil) from the flammable gases.

Pyrolysis Products

The use of raw and residual materials is an important component towards a bio-based economy that protects the environment, climate and resources. With pyrolysis it is possible to process various types of feedstock to produce energy-rich products, that can be further used. These Products are:

Coke:

The solid pyrolysis products depend on the input material and the pyrolysis process. This fine coke and char is excellent for briquetting, energy use, as sorbents, as well as for usage in agriculture

Pyrolysis Oil:

The liquid pyrolysis products are non-polar and can be used as alternativ fuel or further refinded to produce biodiesel fuel (depending on the input material)

Pyrolysis Gas:

The resulting non-condensable pyrolysis gas is mostly consumed by the pyrolysis plant to generate heat energy for the process.